Frequent problems in the supply chain caused by supply chain disruptions and lack of valuable information have made it clear that supply chain professionals must become more resilient to change.

How to become resilient?

Building resilience starts by digitalizing their supply chain to increase visibility and connectivity. This allows teams and partners to access data better and work effectively with their suppliers, vendors, and stakeholders.

4 Frequent Problems in The Supply Chain

A recent Supply Chain Resilience Survey conducted by Quickbase, which interviewed 200.000+ employees in the logistics industry, showed 4 daily problems organizations must deal with.

Inability to Deal with Problems on Time

The main problem for organizations is their inability to deal with disruption or changes. Despite ongoing disruptions, and following the Quickbase research, more than 50% of the companies interviewed stated that they feel only moderately prepared or unprepared for change. Furthermore, 79% of respondents reported dealing with daily or weekly challenges such as changes in production quantity, quality defects, and changes in work patterns.

Domino Effect of Supply Chian Disruptions

In line with the first problem, disruptions severely affect the supply chain workflow. Small disruptions in the supply chain can lead to larger waves at the consumer level. For instance, some of the most common problems they suffer are: higher operating costs, loss of their revenue, and missed customer deadlines, among others.

Disconnectivity in the supply chain

Another problem is disconnected systems and manual processes which cause slow reaction times. Most companies do not manage integrated software handling different and disconnected software. As a result, they get unuseful data and slow reactions to contingencies.

Lack of Full visibility in the Supply Chain

Finally, if logistics managers had visibility into data, it would be easier for them to find new suppliers or compare productivity to optimize sourcing processes. Nevertheless, most organizations do not have real-time visibility, accurate and integrated data, performance metrics, and contract information. Valuable and accurate information is crucial for reducing risks and ensuring that suitable materials and products are procured at the right time and cost, to the right customers.

In conclusion, all the frequent problems in the supply chain are caused by lacking visibility, data, and connectivity.

How to solve frequent problems in the Supply Chain?

Are you tired of supply chain disruptions causing inconvenience and costing your business money? The solution is simple: accurate data and better connectivity in your supply chain with Grydd Os.

Grydd OS

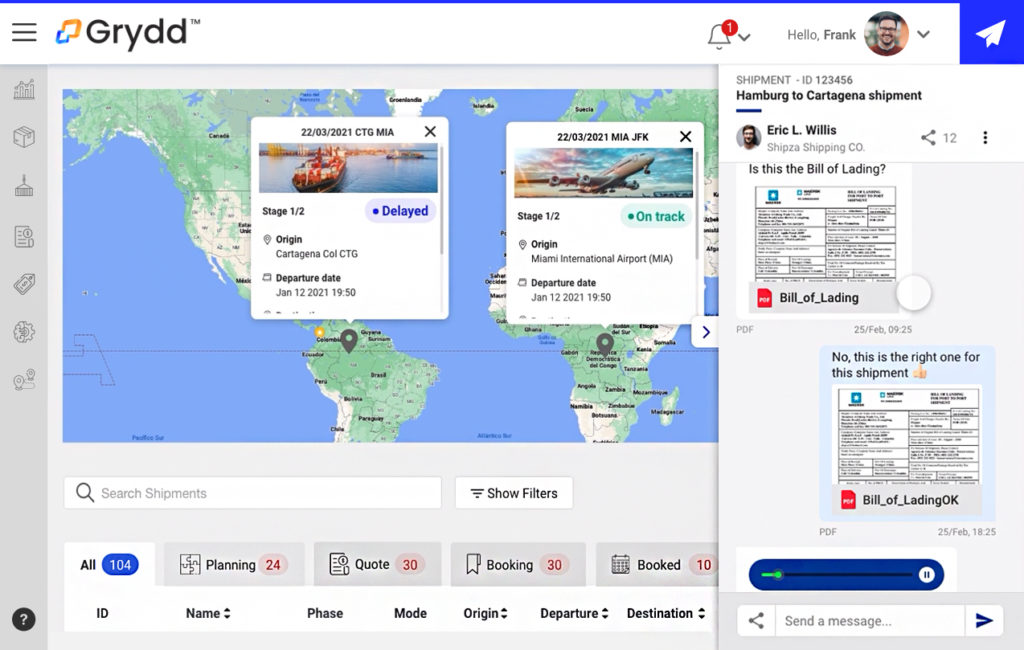

Grydd offers a smart operating system for the supply chain that can help you gain full visibility and access accurate data in real time. This allows you to solve disruptions quickly and even prevent them before they occur. Strong and fast communication among partners and eliminating blind spots in your supply chain is also possible with Grydd OS. All of this can be achieved by digitally connecting and integrating all disconnected software within your company on one platform.

Don’t let supply chain disruptions hold you back any longer. Contact Grydd today and take control of your supply chain.